About

The company was started originally by Matt Dunlop with a business partner. Matt had worked in the textile industry since 2000.

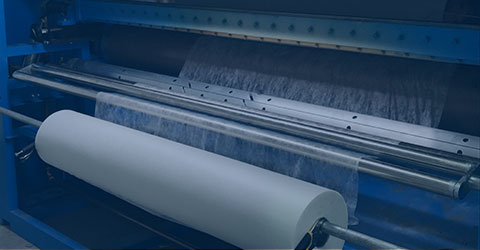

As companies chased higher productivity gains, the machinery and fabric used in production were increasing in size. Matt saw a need for a lamination service to accommodate foam greater than 1900 mm wide.

The Newcastle facility now has two production lines capable of laminating foam widths up to 2400 mm. Five staff members are employed at the Newcastle site.

Matt also saw an increasing demand in the Victorian market for foam lamination services. He recently purchased a business in Melbourne which will officially join the AFL group of companies in October 2017. The facility employs a team of seven and was previously owned by Toyota. As well as servicing the automotive and auto after-market industry, it adds value to in-theatre seating, office furniture, and bedding products.

Environmentally responsible manufacturing is how we do business

The key ingredients to our success

The key to our success is our understanding of our customers’ business. We value all of our customers and potential customers. We work with each one to find out how we can fit into their business.

Once we establish a fit, we work hard to create a cost effective, high quality product. We have a small, experienced team dedicated to the engineering and service necessary to support long-term partnerships.

Our core values include the highest level of customer service and innovative solution-based manufacturing. We’ve got a passion for business and technological development.

Safety is an important element of our success. We abide by strict safety standards.

We’re also careful to track and record all jobs going through the facility at every stage of production. This enables us to trace all stages of the process and products used.

Innovation is also paramount. We’re continuously looking at measures and products to make the process more efficient, not only for us but for each participant in the supply chain.